Understanding Fan Coolers

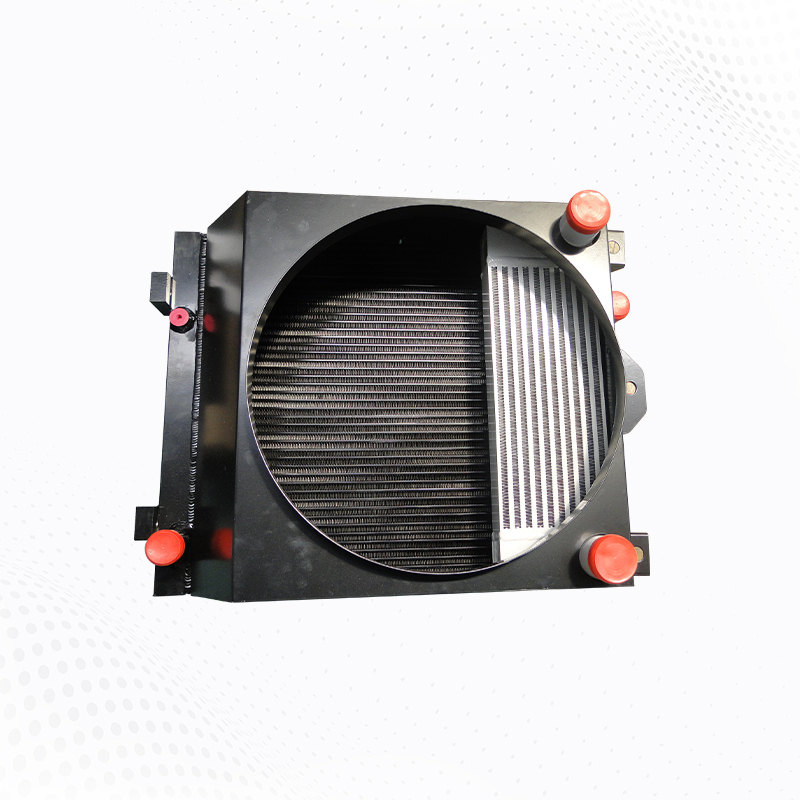

Fan coolers utilize air to dissipate heat from a system. They typically consist of a fan and a heat exchanger, where the fan draws ambient air through the heat exchanger to cool hydraulic fluid or other fluids. In the context of hydraulic systems, a hydraulic oil cooler with a fan is designed to maintain optimal oil temperatures by allowing heat to escape into the air.

Advantages of Fan Coolers:

·Simplicity: Fan coolers are generally simpler in design and easier to maintain than liquid coolers.

·Cost-Effective: They are often less expensive to install and operate, making them a popular choice for smaller hydraulic systems.

·Space-Saving: Fan coolers typically require less space, which is beneficial in compact setups.

Understanding Liquid Coolers

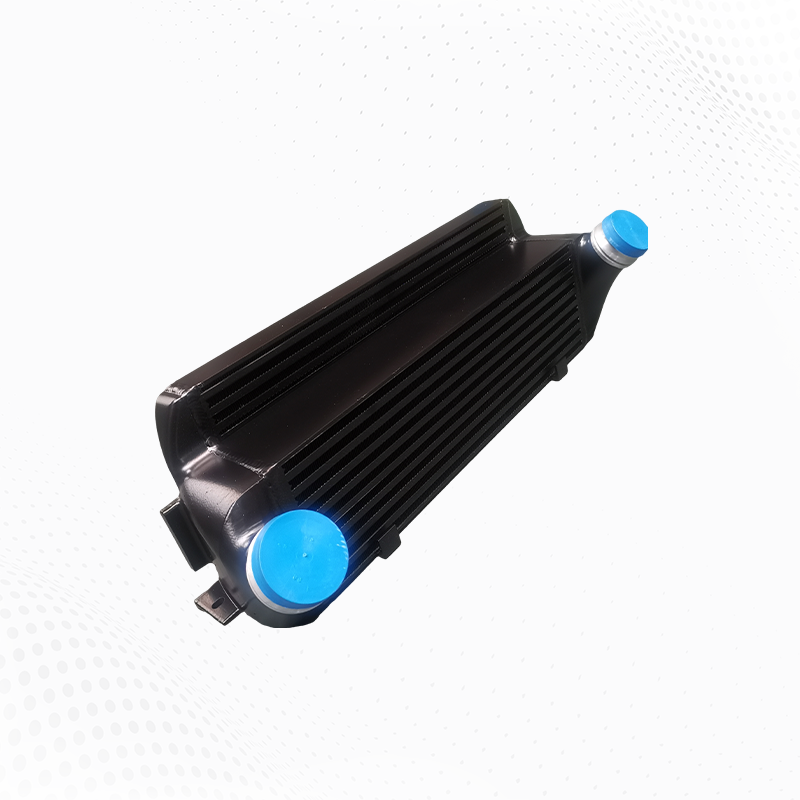

Liquid coolers utilize a liquid medium (usually water or a special coolant) to transfer heat away from the hydraulic fluid. In a hydraulic oil cooler setup, the liquid circulates through a heat exchanger, absorbing heat from the hydraulic oil and dissipating it through another mechanism, such as a radiator or cooling tower.

Advantages of Liquid Coolers:

·Higher Efficiency: Liquid coolers tend to be more efficient at transferring heat, especially in high-load applications where temperatures can rise significantly.

·Better Performance in Extreme Conditions: They can maintain stable temperatures even under heavy usage, making them suitable for larger hydraulic systems.

·Versatility: Liquid coolers can be used in a wider range of applications, including environments where air cooling might not be sufficient.

Key Differences Between Fan Coolers and Liquid Coolers

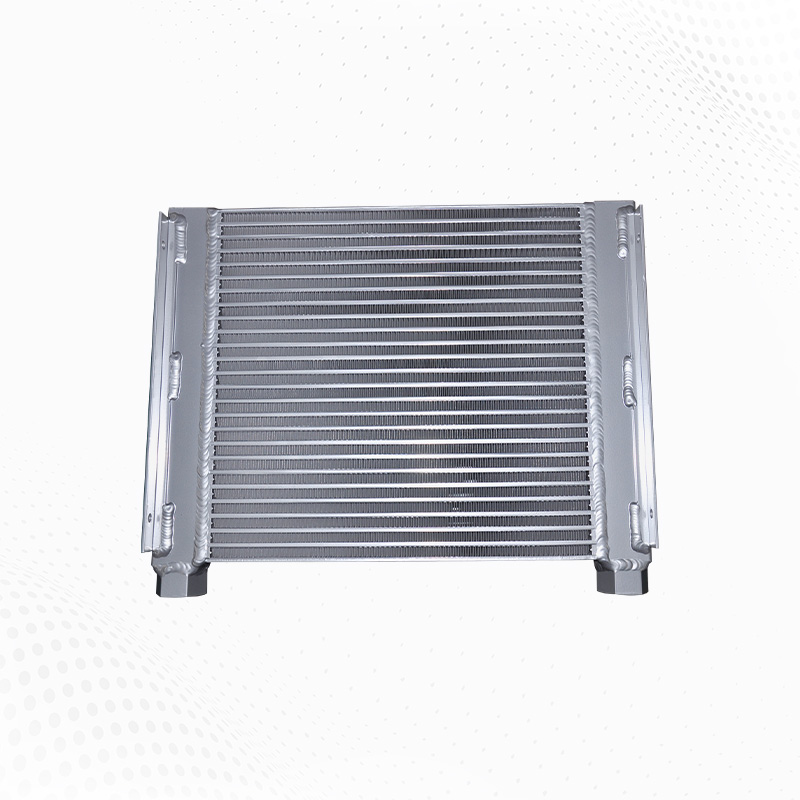

1、Cooling Method: The most significant difference lies in the cooling method. Fan coolers rely on air to dissipate heat, while liquid coolers use a liquid medium, which typically provides more efficient heat transfer.

2、Installation and Maintenance: Fan coolers are generally easier and less expensive to install and maintain. Liquid coolers, while more efficient, can require more complex plumbing and maintenance due to the liquid medium used.

3、Application Suitability: Fan coolers are often best suited for smaller hydraulic systems or applications where space is limited. In contrast, liquid coolers are preferable for larger systems with higher thermal loads, where efficient heat dissipation is crucial.

4、Temperature Control: Liquid coolers provide better temperature control under varying operational conditions, making them ideal for high-performance hydraulic systems that need consistent cooling.

Conclusion

In conclusion, both fan coolers and liquid coolers serve important roles in hydraulic systems, each with its distinct advantages. Fan coolers, including hydraulic oil coolers with air cooling, are straightforward and cost-effective, while liquid coolers offer superior efficiency and performance for demanding applications. Understanding the differences between these cooling systems is essential for selecting the appropriate solution to ensure optimal performance and longevity of hydraulic components.