Article

Efficient Thermal Management for Wind Power with YUDA

As global demand for renewable energy surges, efficient energy production and storage are more crucial than ever. Wind energy has emerged as one of the leading sources of sustainable power; however, it comes with its own set of technical challenges, particularly regarding heat management. Effective cooling systems are essential to maintaining the efficiency and longevity of wind turbines, and that’s where YUDA steps in with its cutting-edge wind energy plate-fin heat exchangers.

Wind Energy Plate-Fin Heat Exchangers: The Key to Enhanced Performance

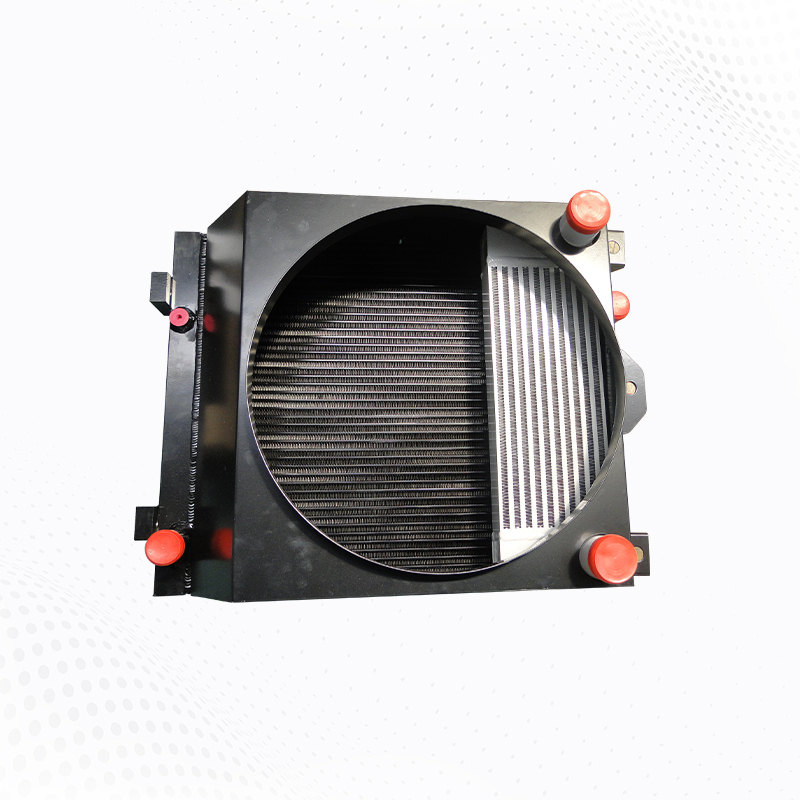

YUDA’s plate-fin heat exchangers are specifically engineered to manage the heat generated during wind energy production. In wind turbines, electrical and mechanical components generate substantial heat that, if left unchecked, can reduce efficiency and lead to equipment degradation over time. A wind energy plate-fin heat exchanger ensures that excess heat is efficiently dissipated, allowing the turbine components to maintain optimal performance.

These specialized heat exchangers operate by channeling heated air or liquid through an intricate network of plates and fins, which maximize surface area and speed up heat transfer. YUDA’s technology has made these systems compact yet highly efficient, tailored for the fluctuating environmental conditions that are typical in wind farms. This innovation has made YUDA a trusted name for heat exchange solutions in the renewable energy sector.

How YUDA's Heat Exchangers Optimize Efficiency

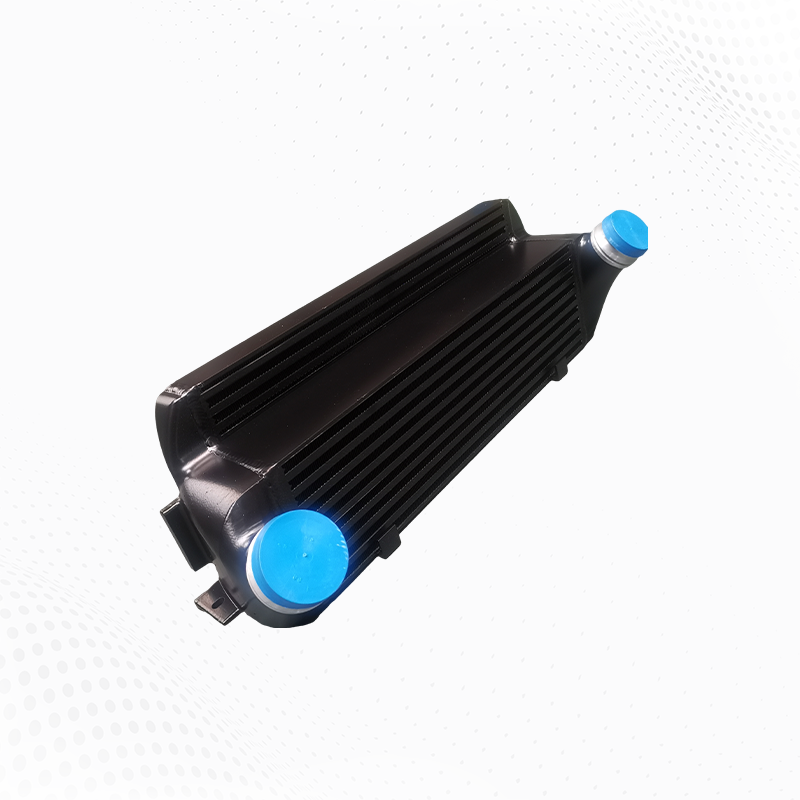

A defining feature of YUDA’s heat exchangers is their focus on boosting the overall wind energy plate-fin heat exchanger efficiency. Using lightweight yet durable materials, YUDA has designed these systems to be resilient against corrosion, moisture, and harsh temperatures—factors that commonly impact wind farms located in challenging environments.

Moreover, the increased wind energy plate-fin heat exchanger efficiency contributes to cost savings for energy providers. By ensuring that turbines operate at lower, more manageable temperatures, YUDA’s technology reduces the need for frequent maintenance, which translates to less downtime and lower operational costs. This streamlined approach to thermal management helps operators maximize their return on investment and achieve stable power outputs.

The Environmental Benefits of YUDA’s Technology

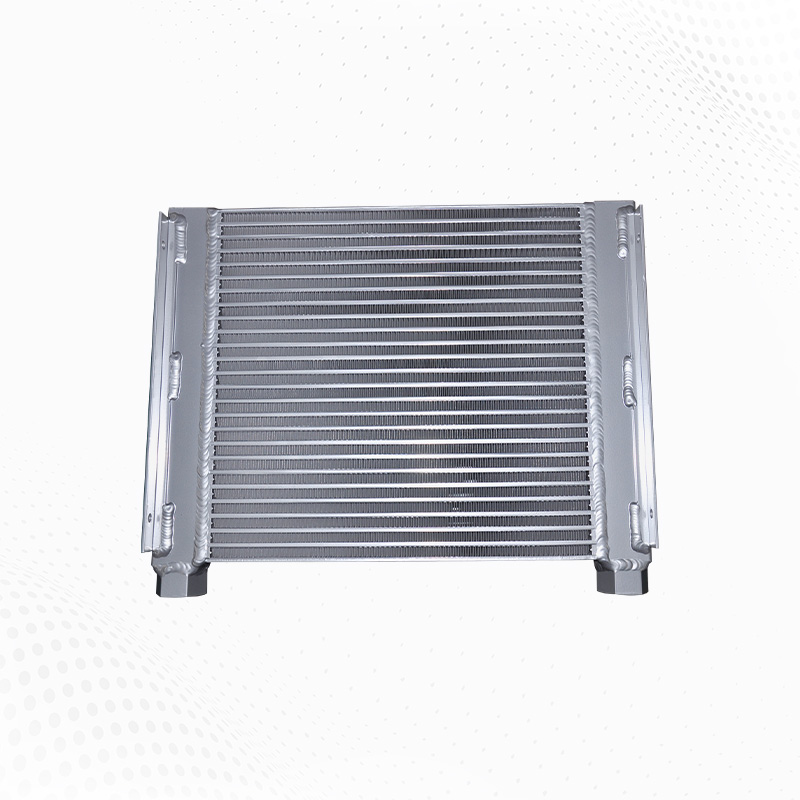

With an emphasis on sustainability, YUDA’s plate-fin heat exchangers are an eco-friendly addition to wind energy systems. The high wind energy plate-fin heat exchanger efficiency enables wind farms to reduce energy losses and extend the lifespan of their equipment. This, in turn, results in less waste and reduced emissions associated with manufacturing and replacing equipment. By contributing to the longevity of renewable energy infrastructure, YUDA is helping wind energy providers achieve their sustainability goals.

Additionally, these heat exchangers support quieter operations in wind farms, which is a key consideration for installations near residential areas. YUDA’s focus on efficiency and environmental friendliness reflects a commitment to sustainable growth in the renewable energy sector.

Future Outlook: Wind Energy and Thermal Efficiency

YUDA’s advancements in wind energy plate-fin heat exchanger technology highlight the growing importance of thermal efficiency in renewable energy production. As wind energy continues to expand globally, the need for efficient heat management solutions like YUDA’s plate-fin heat exchangers will only increase. With their compact design, energy-saving capabilities, and resilience to environmental challenges, YUDA’s heat exchangers are a promising solution for the renewable energy sector’s future needs.

Conclusion

The development of YUDA’s wind energy plate-fin heat exchangers is a crucial step in optimizing the efficiency and longevity of wind energy systems. By addressing the thermal management needs specific to wind power, YUDA is enhancing renewable energy efficiency and contributing to a more sustainable future.